The evolution of industrial training has reached a critical stage as organizations transition toward Industry 5.0 emphasizing synergies between humans and intelligent machines [1]. The complexity of actual industrial systems demands for new type training options and delivery methods not restricted to conventional formats such as PDFs, videos, and in-person instruction that limit personalization, scalability, and adaptability of industrial training [2]. To address these challenges, the XR5.0 Training Platform introduces an innovative revolutionary approach consisting in personalized, immersive, and AI-supported learning through a cloud XR infrastructure.

The XR5.0 Training Platform: From static manuals to immersive and dynamic learning

Developed within XR5.0 project, the XR5.0 Training Platform is a multi-component ecosystem designed to transform traditional training content into interactive, immersive training experiences.

At the core of the XR5.0 Training Platform there is the XR Training Management System that allows for content creation and tailors training programs according to the user skill level and performance comprising two main components:

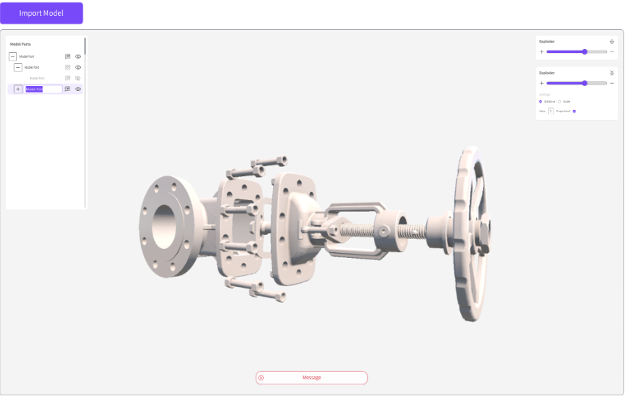

- Training Programs Authoring Tool (TPAT) – A web-based tool that allows training managers to upload and convert traditional materials into XR content. It provides an intuitive interface to build immersive programs using learning paths, quizzes, and workflows. As planned features it will include AI-driven content generation tools for extracting and producing the XR training materials [3]. The figure below shows the TPAT interface for configuring 3D materials.

- XR Training Plugin (XRTP) – A Unity-based plugin for XR devices compatible with HoloLens, Magic Leap and Meta Quest, renders XR training programs created with TPAT. As planned features it will provide personalized interactions, and adaptive interfaces based respectively on the user’s skill level and task performance [4].

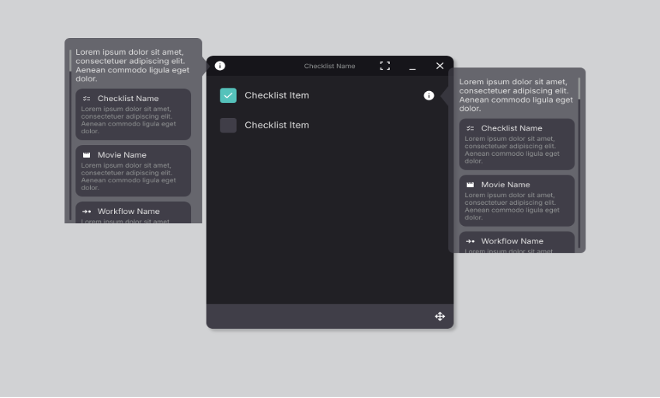

For achieving these features, this system offers a simple and flexible structure for combining the training materials into training programs ,consisting in many-to-many relations which is crucial for creating scalable, modular, and personalized training programs. The figure below depicts the XR panels displaying related training materials associated with both the checklist and individual checklist items.

The XR5.0 Training Platform supports the following modules for converting traditional training materials into XR-based training materials:

- XR Image – Enables trainees to view static diagrams and illustrations in immersive environments, with zoom capabilities for exploring details.

- XR Checklist – Converts procedural instructions from traditional documents into step-by-step bullet points within XR dashboards to guide user actions.

- XR Workflow – Offers sequenced task guidance using rich text enhancing procedural clarity during a complex task.

- XR Video – Integrates annotated instructional videos with chapters allowing real-time visualisation inside XR environments.

- XR Assistant – An AI voice assistant included in the XR interface trained on training materials to provide real-time guidance, answer procedural questions and help users in navigating the training content.

- XR 3D Model Explorer – Provides exploded views and interactive part visualization, supporting users in exploring 3D content from industrial assemblies.

- XR 3D Workflow – Extends the XR Workflow concept by integrating animated 3D models to offer a sequenced task guidance using 3D models.

- XR Quiz – Implements assessment modules to evaluate user knowledge, task performance, and training retention.

Conclusion:

The XR5.0 Training Platform may contribute to significant advancements in industrial training by shifting from static and conventional formats to immersive, interactive, and personalized learning experiences. Through its suite of XR modules, ranging from XR visualizations and workflows to AI-guided assistance, it equips operators with the tools needed to perform complex tasks more effectively. This platform aims to enhance training engagement, retention, and adaptability to individual learning needs. As the platform evolves, incorporating AI-driven automation and advanced personalization will further strengthen its capabilities and alignment with Industry 5.0 principles. This positions XR5.0 as a scalable, human-centric solution that meets the demands of novel industrial environments.

References:

[1] Zalozhnev, A.Y. and Ginz, V.N. (2023). Industry 4.0: Underlying Technologies. Industry 5.0: Human-Computer Interaction as a Tech Bridge from Industry 4.0 to Industry 5.0. 9th International Conference on Web Research (ICWR).

[2] Kiourtis, A. et al. (2024). XR5.0: Human-Centric AI-Enabled Extended Reality Applications for Industry 5.0. 36th Conference of Open Innovations Association (FRUCT), Lappeenranta, Finland, 2024, pp. 314-323.

[3] Oliveira, J. Saraiva, T., Manoj Shah, H., et al. (in press). XR Training in Industry 5.0: Advancing Human-Machine Collaboration with the XR5.0 Training Platform. XR Salento 2025. Lecture Notes in Computer Science. Springer, Cham.

[4] Matteri, D., Masiero, S., Dell’Oca, S., Montini, E., Cutrona, V., & Canetta, L. A. (2025). Protocol for Human-Centric Adaptive User Interfaces: From Static Interaction to Behaviour-Driven Adaptation. (2025). [pre-print].