Effective knowledge management is critical for industrial enterprises looking to optimize their maintenance and repair processes. As part of the groundbreaking XR5.0 research project, vector databases have emerged as a powerful solution for capturing, organizing, and delivering critical knowledge seamlessly to technicians working in augmented reality (AR) environments.

Traditional methods of knowledge management, such as document repositories and structured databases, often fall short when real-time context-aware information retrieval is necessary. This is particularly evident in remote maintenance scenarios where technicians require immediate access to precise and relevant procedural knowledge. The XR5.0 project addresses this challenge by utilizing vector databases—advanced, semantic-driven systems capable of delivering highly relevant and context-sensitive information in real-time.

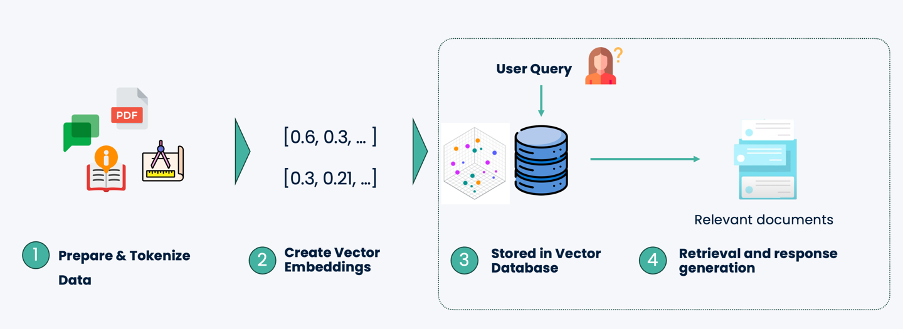

Vector databases operate by converting text, images, and structured data into vector embeddings, effectively capturing the semantic meaning of the content (Figure 1). Within XR5.0’s AR-based remote maintenance scenarios, this means technicians receive instant access to accurate, contextually relevant troubleshooting steps, historical maintenance logs, and detailed instructions tailored precisely to the current maintenance task. For instance, when a technician wearing an XR headset like the HoloLens 2 encounters an issue during equipment calibration, the vector database instantly retrieves and presents the most relevant knowledge artifacts, dramatically improving troubleshooting efficiency.

Integration with XR5.0’s AI-driven features further enhances the capability of these databases. The AI component interprets the technician’s context—location, equipment type, prior maintenance activities—and quickly searches the vector database to provide exactly the right guidance at the right moment. Additionally, this AI-enhanced knowledge retrieval continuously learns and adapts, refining its suggestions over time and ensuring a continuous improvement in maintenance procedures and technician performance.

This innovative approach implemented by XR5.0 significantly improves remote maintenance processes by reducing downtime, increasing first-time-fix rates, and enhancing technician satisfaction. Moreover, by ensuring that crucial expert knowledge remains readily available and instantly accessible, vector databases contribute to greater resilience and operational efficiency in modern industrial environments.

In essence, harnessing vector databases within XR5.0 represents a fundamental shift toward smarter, faster, and more reliable knowledge management—essential for the next generation of Industry 5.0.