Demo Highlight from XR5.0 Horizon Europe Project

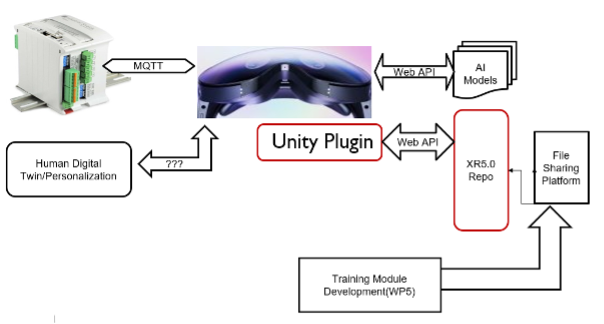

As part of the XR5.0 Horizon Europe project, a collaborative effort between SPACE HELLAS and SYN is delivering innovative XR-based solutions to strengthen training and support in the industrial domain. A recent demonstration from the XR5.0 project highlights how immersive and intelligent technologies can significantly improve both the effectiveness and safety of product assembly and repair processes — particularly in the context of complex edge devices used in critical infrastructure environments.

Why This Matters

Modern industrial systems increasingly rely on distributed IoT edge devices for automated control and security management. However, these devices often require complex configuration and maintenance, demanding high skill levels and consistent accuracy from field technicians. Errors in assembly or repair can lead to costly downtime, inefficiencies, or even safety risks. The demo showcases how AI-augmented XR applications can address these challenges by offering intuitive, adaptive, and immersive support experiences.

What Was Demonstrated?

The showcased solution is built around two core use cases (UCs), each reflecting a major operational need in industrial environments:

Use Case 1 – Personalized Training for Edge Device Assembly

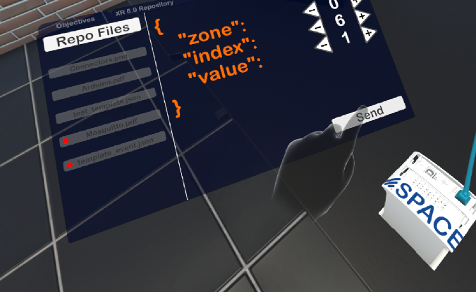

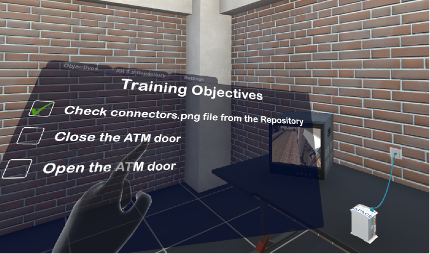

This use case focuses on training technicians of various skill levels using personalized VR/AR workflows. By blending AI with 3D visualizations and interactive guidance, the system allows trainees to:

- Access contextual documentation and technical instructions,

- Interact with high-fidelity digital twins of edge devices in a virtual training environment,

- Follow tailored step-by-step procedures based on their experience level.

Key innovation lies in the adaptive learning engine, which uses AI to generate and adjust training paths in real-time. From entry-level workers to more advanced technicians, each participant receives just the right amount of guidance through:

- Immersive, skill-specific XR modules,

- Embedded animations and simulation tools for better knowledge retention,

- Real-time performance monitoring and feedback mechanisms.

All XR content is delivered through lightweight, wearable headsets, with computational load handled server-side via cloud-based APIs — allowing for scalability, smooth user experiences, and lower hardware requirements.

Use Case 2 – Remote Instructions for Repairs

The second use case addresses repair operations through AI-powered remote assistance. Technicians are equipped with AR headsets that allow them to receive real-time, context-aware instructions while working directly on the hardware. This setup supports:

- Live support from remote experts with visual annotations overlaid in the technician’s field of view,

- Integrated access to diagnostic data and sensor information in real-time,

- AI-driven fault detection and repair guidance customized to technician expertise.

Whether it’s identifying anomalies or applying corrective actions, the system adapts its content to the user’s needs. Less experienced technicians receive in-depth walkthroughs, while experts get concise prompts — both of which significantly reduce troubleshooting time and prevent errors.

Impact and Added Value

The demo illustrates how XR and AI technologies can elevate operational resilience in industrial settings. The benefits are tangible:

- Reduced training and repair time,

- Increased task accuracy and technician confidence,

- Scalable support for diverse skill profiles,

- Enhanced safety and reduced equipment downtime.