Extended Reality in the Smart Factory: Accelerating Innovation, Collaboration, and Efficiency

As we usher in the era of Industry 5.0, smart factories are becoming more than just automated production environments, they’re transforming into digitally orchestrated ecosystems where people and machines collaborate seamlessly. One of the driving forces behind this shift is Extended Reality (XR), an umbrella term that includes Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR). In the XR5.0 project, we explore how XR technologies are revolutionizing smart manufacturing, not just by making processes more efficient, but by reshaping how we train, troubleshoot, plan, and communicate.

XR as a Game-Changer in Workforce Training

One of the most impactful uses of XR in our smart factory initiatives is in worker training. As production systems become increasingly complex and customized, equipping new or existing employees with the skills to operate and maintain machinery safely and efficiently is more challenging than ever.

With XR, we’re able to create interactive, immersive training environments that simulate real-world scenarios. Workers can explore and interact with digital twins of machines, rehearse maintenance procedures, and understand intricate machine operations, all in a safe and controlled environment.

This approach significantly reduces onboarding time and improves knowledge retention. More importantly, it allows trainees to fail safely, learning through experience without the risks or costs of downtime or damage to actual equipment.

Supporting Live Interventions and Remote Troubleshooting

XR doesn’t stop at training, it extends into live support and operational assistance. During a real intervention, for example, AR headsets or tablets can overlay contextual information directly onto a worker’s field of view, showing instructions, warnings, or sensor data. This greatly improves accuracy and reduces errors during complex tasks.

We also leverage XR to enable remote collaboration. When a technician encounters a machine fault, an expert can connect via a remote call, view what the technician sees, and guide them through the troubleshooting process. This approach minimizes the need for on-site visits and allows real-time problem-solving across locations.

Virtual Production Tours and Invisible Insights

Beyond operations and maintenance, XR has proven invaluable for showcasing and communicating smart factory processes, especially to visitors, partners, or stakeholders unfamiliar with the factory floor. Through virtual production tours, users can navigate a digital replica of the factory, explore different stages of production, and visualize workflows.

But XR can do even more. In a smart factory, many of the most critical interactions are invisible, like machine-to-machine communication, data exchanges over the industrial IT network, or the flow of orders through ERP systems. With XR, we can make these hidden layers visually accessible, offering insights into how the factory “thinks” and “communicates,” not just how it moves parts.

This capability enhances transparency, trust, and understanding, particularly during client presentations, audits, or educational visits.

Spatial Planning and Layout Optimization

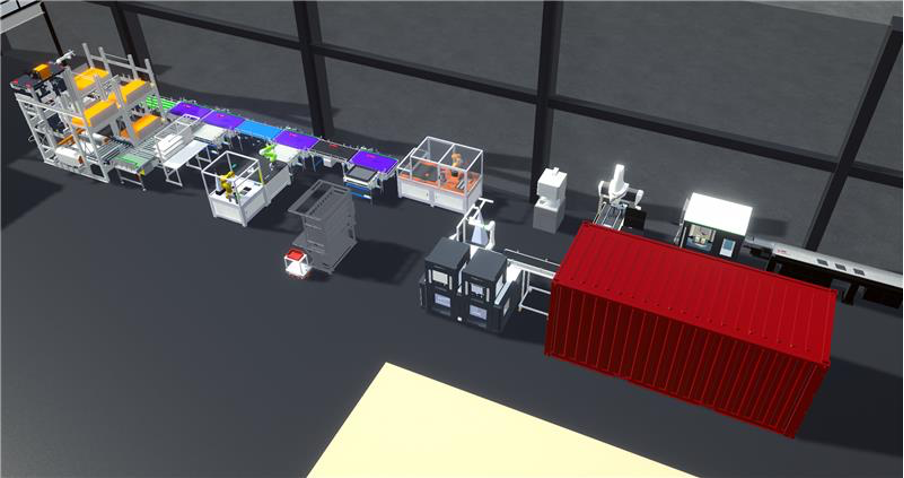

Smart factories are dynamic, machines get upgraded, layouts are reconfigured, and new workflows are introduced. In such an environment, planning spatial arrangements efficiently is crucial. This is where XR again proves its worth.

By importing CAD models of machines and installations into a shared 3D environment, teams can experiment with layout changes in real-time. They can walk through the virtual production space, check for bottlenecks, simulate maintenance access, and ensure compliance with safety distances, all before moving a single machine.

This not only accelerates the planning process but fosters collaborative decision-making. Stakeholders, from engineers to operators, can all view and interact with the same virtual setup, reducing misunderstandings and aligning perspectives.

Current Limitations and Challenges

While the benefits of XR in smart factories are clear, we also need to acknowledge its current limitations.

- Hardware constraints: XR devices can still be bulky, expensive, or limited in battery life and durability, especially in industrial environments.

- Content creation and maintenance: Developing accurate, interactive 3D content and keeping it up to date requires significant effort and expertise.

- Integration complexity: To be truly useful, XR needs to integrate with existing IT, IoT, and OT systems, something that can be technically and organizationally challenging.

- User acceptance: Some users may be hesitant to adopt XR tools due to unfamiliarity or concerns about comfort and usability.

However, these limitations are not showstoppers, they are areas of active research and development. With the XR5.0 initiative, we are continuously testing new devices, improving interoperability with factory systems, and developing best practices to ensure smooth deployment and long-term value.

Conclusion: XR as a Strategic Enabler

XR is no longer a futuristic add-on, it’s a strategic enabler in the transformation of smart manufacturing. At XR5.0, we’ve seen how these technologies can enhance human capabilities, streamline collaboration, and unlock a new level of factory intelligence.

As we look to the future, the integration of XR with AI, edge computing, and real-time data analytics will only deepen its impact. The smart factory is not just automated, it’s becoming intuitive, visual, and interactive, thanks to the power of Extended Reality.